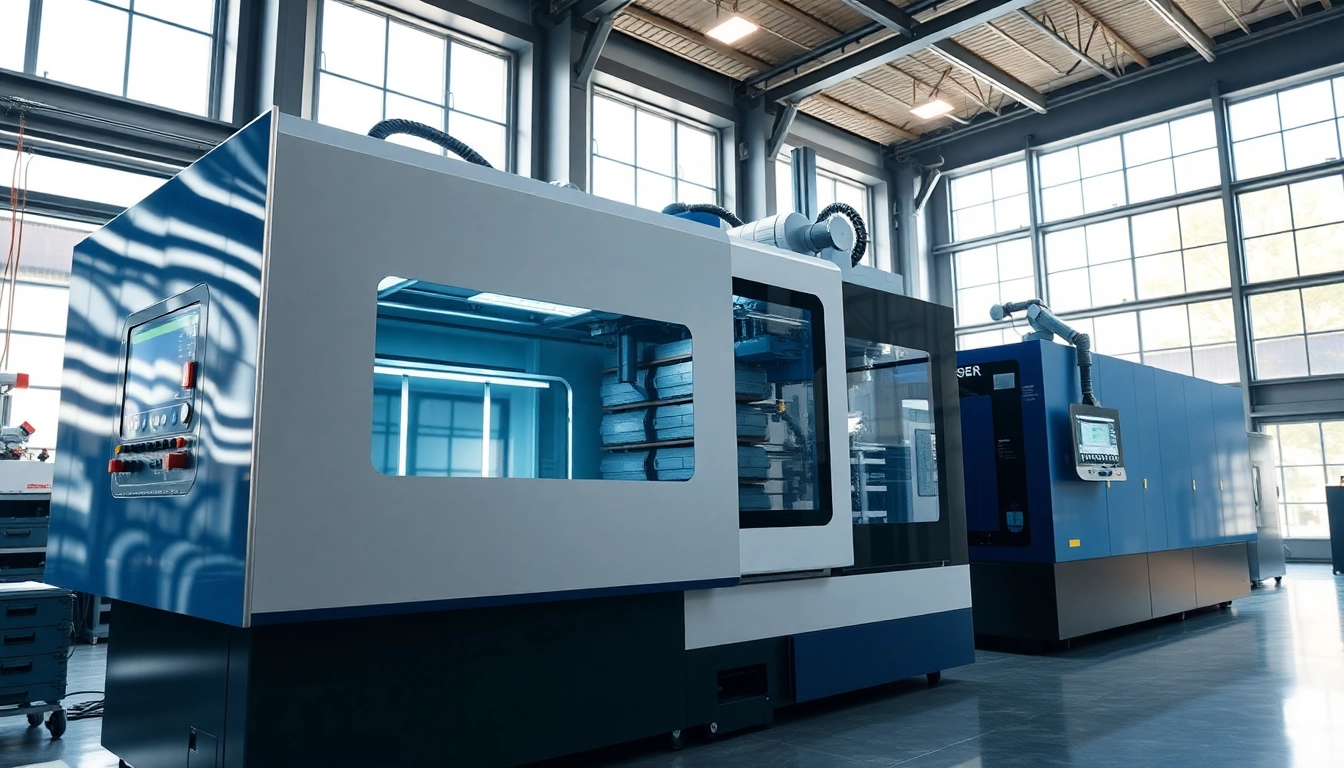

Understanding the Injection Molding Machine and Its Importance

The injection molding machine is an essential piece of equipment in the manufacturing industry, renowned for its ability to produce high volumes of plastic parts efficiently and consistently. As industries evolve, the demand for injection molding technology continues to grow, with advances leading to more sophisticated machines that enhance productivity and reduce costs. With the rise of electric and hybrid models, such as those offered by Topstar, the efficiency and sustainability of the production process have significantly improved. When exploring options, Injection Molding Machine solutions provide comprehensive insights into modern manufacturing capabilities.

What is an Injection Molding Machine?

An injection molding machine is designed to transform raw plastic pellets into usable products through a precise injection process. The machine heats the plastic until it melts, then injects it into a mold where it cools and solidifies into the desired shape. This method is highly efficient for producing complex parts with intricate designs, making it a staple in many industries, including automotive, consumer goods, and electronics. The ability to mass-produce identical parts quickly and effectively is what makes injection molding such a valuable manufacturing process.

Key Components and Their Functions

The functionality of an injection molding machine relies on several key components:

- Injection Unit: This component melts the plastic and injects it into the mold. Its design affects cycle times and product quality.

- Clamping Unit: It holds the mold in place during the injection process. The clamping force must be adequate to prevent the mold from opening due to the pressure of the injected material.

- Control System: Modern machines are equipped with advanced control systems that allow for precise monitoring and adjustments throughout the molding process, enhancing both efficiency and accuracy.

- Mold: The mold defines the shape of the final product. Molds can be customized for various applications, influencing everything from production speed to product quality.

Each component plays a vital role in ensuring that the injection molding process is efficient, accurate, and capable of producing high-quality products consistently.

Applications Across Industries

Injection molding machines are versatile and used across multiple industries, including:

- Automotive: Manufacturing parts such as dashboard components, battery housings, and other automotive accessories.

- Consumer Goods: Producing everyday items like containers, toys, and household appliances.

- Medical Devices: Creating precise components for medical instruments and devices, which require high levels of accuracy and cleanliness.

- Electronics: Molding cases and components for electronic devices, ensuring both durability and design integrity.

With the increasing complexity of products across these industries, advanced injection molding technologies are more critical than ever.

Benefits of Electric Injection Molding Machines

Electric injection molding machines offer numerous benefits over their hydraulic counterparts, leading to increased adoption in manufacturing settings.

Enhanced Precision and Control

One of the primary advantages of electric injection molding machines is their ability to provide enhanced precision and control. With discrete intelligent drive systems, as seen in Topstar’s TEⅡ series, manufacturers can achieve superior position and pressure control. This results in higher consistency in product quality and a reduction in defects during production.

Energy Efficiency and Cost Savings

Electric machines typically consume less energy than hydraulic machines because they operate on electricity rather than hydraulic fluid. This efficiency translates into lower operational costs over time. Moreover, the precise control of the electric systems helps to reduce material wastage, further driving down costs and promoting sustainable manufacturing practices.

Environmental Impact and Sustainability

The shift towards electric injection molding machines reflects a broader trend in the manufacturing industry to adopt more environmentally friendly practices. Electric machines produce less noise and emit fewer greenhouse gases compared to traditional hydraulic machines. As sustainability becomes a key focus for manufacturers, the electric injection molding machine is a step in the right direction.

Topstar’s Advanced Electric Injection Molding Models

Topstar offers a range of advanced electric injection molding machines designed to meet the diverse needs of modern manufacturing.

Overview of the TEⅡ Series

The TEⅡ series features all-electric models that leverage advanced technologies for improved productivity and efficiency. These machines utilize high-rigidity templates for clamping units, which stabilize the product and enhance mold protection. The modular design allows for quick adjustments to various working conditions, accommodating the needs of different production processes.

Insights into the TMⅡ Series

Topstar’s TMⅡ series introduces servo-driven injection molding machines that integrate the injection molding process into a single control interface. This integration allows automatic compensation during the mold opening process and real-time feedback, making it easier for operators to manage production. The precision achieved in this series enables manufacturers to create products with complex appearances and exact specifications.

Exploring the TH Series for Large-Scale Production

For larger-scale operations, the TH series offers direct press type injection molding machines. Divided into small, medium, and large categories, these machines are designed for high output and efficiency. The two-plate direct pressure center clamping structure provides the maximum mold opening stroke, making it ideal for producing large-format, deep-cavity products. This series represents a robust solution for manufacturers looking to optimize their production capabilities.

Challenges and Solutions in Injection Molding

While injection molding technology has advanced significantly, manufacturers still face several challenges in the production process.

Common Issues Faced by Manufacturers

Some of the challenges include material flow inconsistencies, mold design limitations, and cycle time optimization. These issues can lead to defects in the final product and decreased production efficiency.

Implementing Automation for Efficiency

Automation is a key strategy for overcoming many of these challenges. By integrating robotic systems with injection molding machines, manufacturers can enhance precision, reduce cycle times, and minimize labor costs. Robotic arms can perform tasks such as part removal, quality inspection, and packing, further streamlining the production process.

Case Studies of Successful Integration

Several manufacturers have successfully integrated automation into their injection molding processes, resulting in significant improvements in efficiency and product quality. For instance, a plastic parts manufacturer increased their output by 30% after implementing robotic systems alongside their injection molding machines, drastically reducing manual errors and improving workplace safety.

The Future of Injection Molding Machines: Trends and Predictions

As we look toward the future, several trends are shaping the injection molding landscape.

Technological Innovations on the Horizon

Innovations in materials science, machine learning, and data analytics are expected to revolutionize the injection molding industry. For example, the development of smart materials that change properties on demand could lead to entirely new applications for injection molding machines.

Market Growth Projections for 2025

The global injection molding machine market is projected to grow substantially by 2025, driven by the increasing demand for efficient production processes. As industries continue to seek cost-effective and environmentally friendly solutions, electric and hybrid machines will likely dominate the market.

Preparing for Industry Changes

Manufacturers must prepare for these industry changes by investing in new technologies and training their workforce. Staying ahead of the curve will ensure that businesses remain competitive in a rapidly evolving market.