Understanding Cutting Equipment: An Overview

Definition and Importance

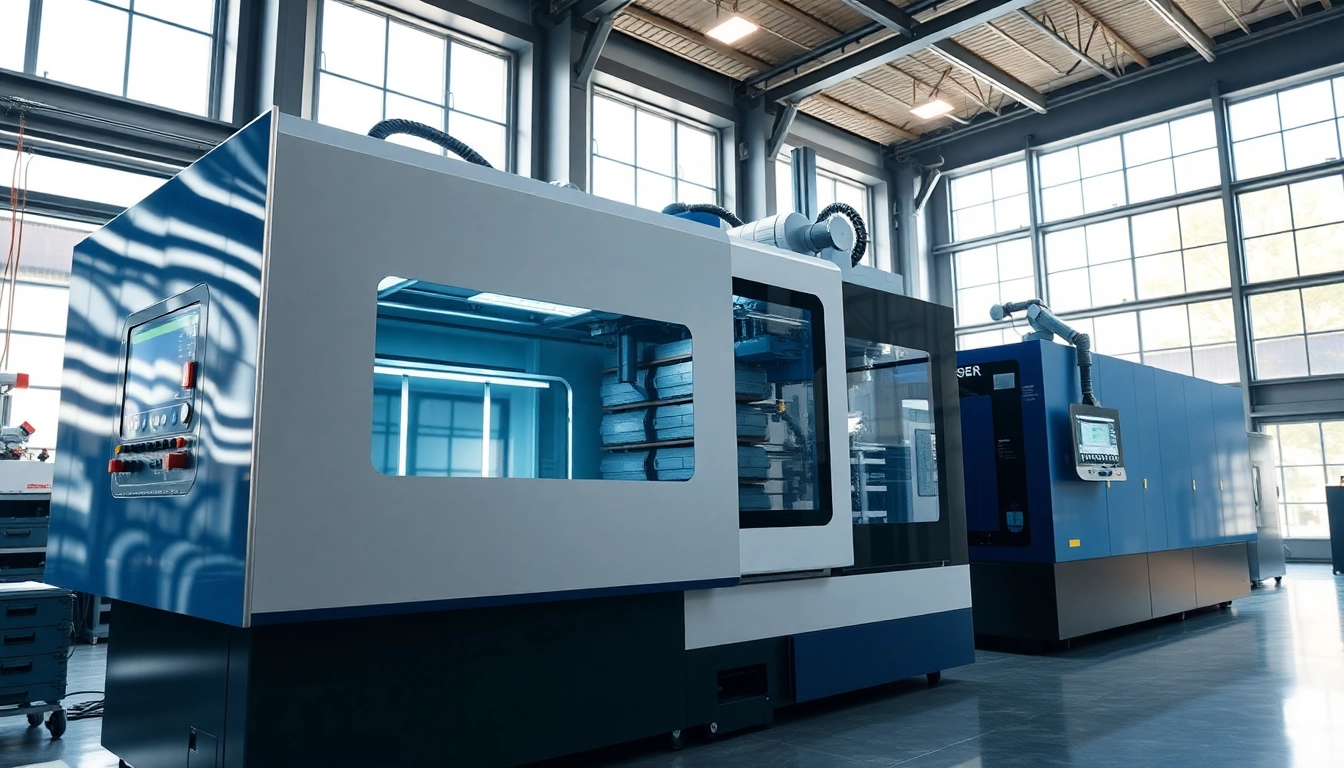

Cutting equipment refers to a variety of tools and machines designed to slice through a wide range of materials. These tools are fundamental in industrial and manufacturing processes, where precision, efficiency, and safety are paramount. From woodworking to metal fabrication, the ability to cut materials accurately determines the quality of the final product and affects overall productivity.

The significance of cutting equipment extends beyond mere practicality. It facilitates innovation, allows for intricate designs, and empowers industries to expand their capabilities. Whether it’s for large-scale production or intricate crafts, the right cutting equipment can make a significant difference in operational efficiency.

Types of Cutting Equipment

Cutting equipment comes in various types, each designed for specific tasks and materials. Here are some of the most commonly used:

- Circular Saws: Versatile tools for cutting wood, metal, and plastic through rotational blades.

- Band Saws: Ideal for intricate curves and shapes, tailored primarily for wood and metal.

- CNC Machines: Computer-controlled equipment that automates precise cutting in multiple materials.

- Laser Cutters: Use focused laser beams for high precision cuts, primarily in metal and plastics.

- Plasma Cutters: Effective for cutting thick metal sheets using a high-velocity jet of ionized gas.

Applications Across Various Industries

The applications of cutting equipment span various sectors, including:

- Manufacturing: Various tools are essential in the production of components for machinery, vehicles, and electronics.

- Construction: Equipment such as saws and plasma cutters are crucial for framing, roofing, and metalwork.

- Aerospace: Precision cutting is vital for creating components that must meet strict safety and quality standards.

- Art and Craft: Laser cutters and band saws enable artisans to create detailed designs from different materials.

- Automotive: Cutting equipment helps in manufacturing parts that require high precision and durability.

Key Features of Cutting Equipment

Material Types and Their Influence

The type of material being cut significantly influences the choice of cutting equipment. Different materials, such as wood, metal, and composites, exhibit unique properties that dictate the necessary tools. For instance, soft materials like plastic can be easily cut with less powerful tools, whereas metals generally require more robust cutting machines capable of withstanding higher pressure and providing finer finishes.

Power Sources and Mechanisms

Cutting equipment operates on various power sources, including electric, hydraulic, and mechanical systems. Electric saws are popular due to their ease of use and accessibility, while hydraulic systems excel in industrial applications requiring immense power for heavy materials. Moreover, understanding the mechanism—be it rotary, reciprocating, or laser-based—helps in selecting the appropriate equipment for specific tasks.

Durability and Maintenance Considerations

Durability is a critical feature of cutting equipment, directly impacting operational costs. High-quality materials and robust designs ensure that equipment withstands daily wear and tear, resulting in minimized downtime. Regular maintenance, including cleaning, lubrication, and inspections, is essential to extend the equipment’s longevity and prevent costly repairs or replacements. A well-maintained tool ensures consistent performance and safety throughout its life cycle.

Choosing the Right Cutting Equipment

Assessment Based on Project Needs

Choosing the right cutting equipment starts with a clear assessment of project requirements. Factors such as materials to be cut, desired precision, volume of work, and environmental conditions all play a role in the decision-making process. For example, a woodworking project may need a different type of saw than a metal fabrication task. Understanding specific project implications helps in making informed choices.

Cost vs. Quality: What to Consider

When selecting cutting equipment, striking a balance between cost and quality is vital. While budget constraints may tempt buyers to opt for cheaper options, investing in high-quality tools often results in long-term savings. High-quality equipment typically offers better performance, enhanced safety features, and less frequent breakdowns, justifying the initial investment.

Evaluating Safety Features

Safety is paramount when using cutting equipment, given the inherent risks involved. Inspecting various safety features—such as blade guards, emergency shut-offs, and ergonomically designed handles—can significantly reduce the risk of accidents. Ensure that equipment complies with safety standards and regulations pertinent to current operational environments.

Best Practices for Using Cutting Equipment

Preparing for Safe Operation

Preparing the work area and ensuring the right setup is crucial for safe operation. This includes wearing personal protective equipment (PPE), ensuring all safety guards are in place, and familiarizing oneself with the equipment’s manual. Prior to cutting, it’s essential to check for any obstructions, ensure proper lighting, and verify that equipment settings are appropriate for the material in use.

Regular Maintenance and Care Tips

Consistent maintenance is key to prolonging the life of cutting equipment. Regular practices include cleaning blades after use, inspecting for signs of wear or damage, and lubricating moving parts to prevent rust and ensure smooth operation. Documenting maintenance activities helps track performance and address potential issues proactively.

Training and Skill Development

Providing training to operators on the proper use of cutting equipment is essential for safety and efficiency. Training programs should cover machine operation, maintenance protocols, and emergency procedures. Offering ongoing skill development sessions can enhance operators’ abilities and ensure adherence to the latest safety standards and industry practices.

Common Challenges with Cutting Equipment

Troubleshooting Common Issues

Operators often face challenges such as blade dullness, material binding, and misalignment. Implementing troubleshooting techniques can help identify and resolve these issues. For instance, ensuring that blades are sharpened at regular intervals can reduce cutting resistance, while proper calibration helps maintain cutting accuracy.

Understanding Wear and Tear

Understanding wear and tear on cutting equipment is vital for maintaining performance and safety. Common signs of wear include noise during operation, vibration, and inconsistent cutting results. Monitoring these indicators can preemptively alert operators to necessary repairs, ultimately ensuring equipment remains in optimal working condition.

Innovation Trends in Cutting Technology

The realm of cutting technology continuously evolves, driven by the demand for increased efficiency and precision. Recent trends include the integration of smart technology, allowing for real-time monitoring and adjustments to cutting parameters. Developments in materials engineering have also led to the design of longer-lasting blades, further enhancing equipment longevity and performance.

FAQs

1. What types of cutting equipment are most commonly used?

Common types include circular saws, band saws, and CNC machines, each tailored for specific cutting tasks.

2. How do I choose the right cutting equipment?

Consider factors like material type, project scale, safety features, and budget to choose the most suitable equipment.

3. What are best practices for maintaining cutting equipment?

Regularly clean, lubricate, and inspect tools for wear to extend their life and ensure optimal performance.

4. How can I improve safety while using cutting equipment?

Always wear personal protective equipment (PPE), follow manufacturer instructions, and undergo proper training.

5. What innovations are emerging in cutting technology?

Trends include automated systems, smart technology integration, and improved materials for greater efficiency and safety.